5 Practical Tips for Optimizing Die Casting Mold Design

The success of die casting hinges on mold design, which directly impacts product quality and production efficiency. For consumer-grade parts like automotive throttle valve bodies, a poorly designed mold can lead to scrap rates as high as 48%. How can technology optimize this process? Drawing from a mold flow analysis case, this article shares five practical tips to improve mold design, reduce defects, and ensure consistency in your die casting projects.

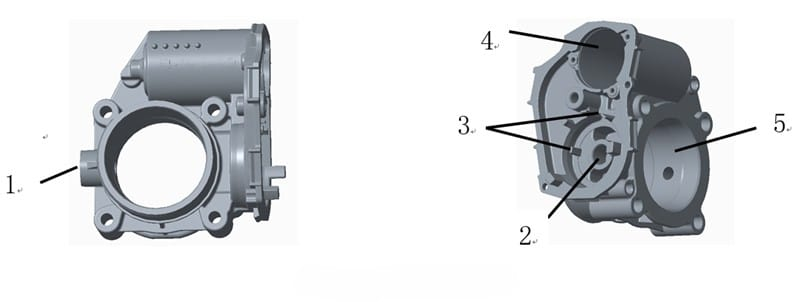

Case Study: Mold Challenges with the Throttle Valve Body

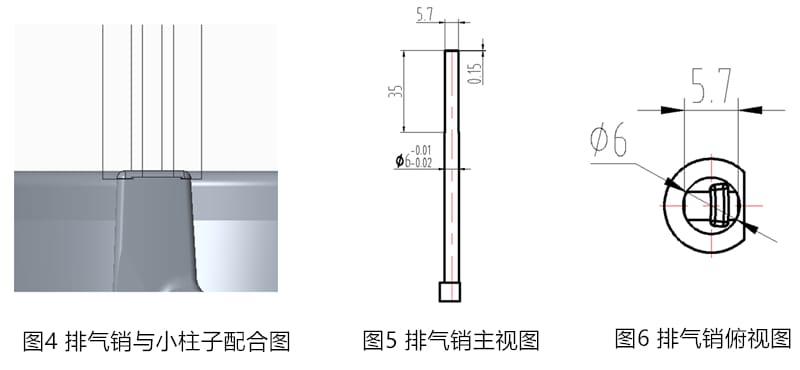

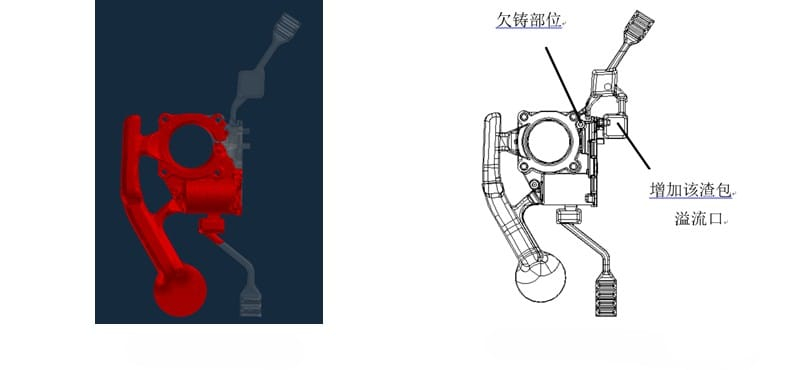

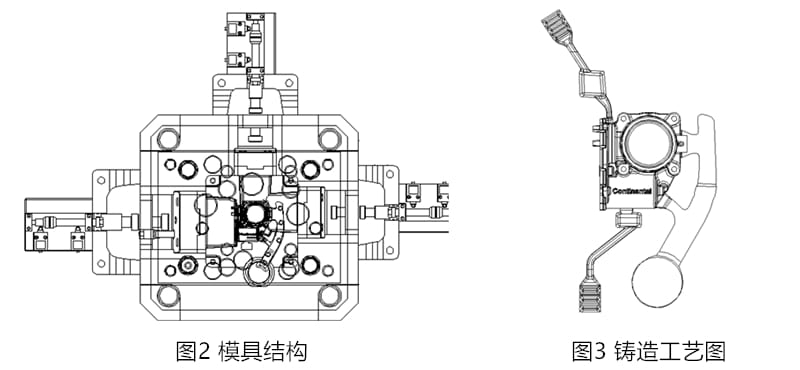

The B15B throttle valve body, with uneven wall thickness (1.7-5mm) and deep-cavity features (1.3mm × 9mm pins), uses a 1-cavity mold with three hydraulic core-pull sliders. Despite this, production faced undercasting and porosity issues, resulting in a 48.52% scrap rate.

Alt: Schematic of a 1-cavity die casting mold with three hydraulic core-pull sliders for the B15B throttle valve body.

Mold flow analysis helped us identify solutions, leading to these five tips:

5 Practical Optimization Tips

Add Venting for Deep Cavities

Undercasting in the limit pins resulted from trapped gas in deep cavities. Adding a vent pin (6mm diameter, flattened 0.15-0.2mm) near the pin improved filling—ideal for any deep-cavity part.

Alt: Diagram showing a vent pin installed near limit pins to prevent undercasting in die casting molds.Enhance Overflow Systems

Peripheral undercasting occurred at the fill end due to missing vents. Adding a slag trap and overflow vent expelled cold material and gases, ensuring complete molding.

Alt: Layout of a slag trap and overflow vent in a die casting mold to eliminate peripheral undercasting defects.Boost Core Cooling

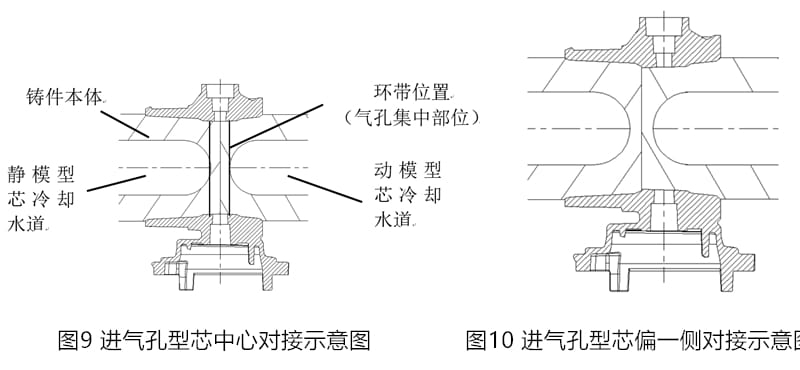

Porosity in the air intake ring stemmed from heat buildup at core joints. Extending the moving core’s water channel to the ring area created a chill layer, slashing porosity.

Alt: Cross-section of a die casting mold showing an extended cooling channel in the moving core to minimize porosity.Adjust Inner Gate Angle

The inner gate’s 27° slope caused flow issues. Raising it to 35° (within the 30°-45° standard) smoothed alloy flow and reduced gate porosity.

Alt: Illustration of an optimized 35° inner gate slope in a die casting mold for improved molten alloy flow.Leverage Mold Flow Analysis

All improvements relied on mold flow simulations, which highlighted gas traps, cooling gaps, and flow paths—offering data-driven precision.

Applications

These tips extend beyond throttle valves to consumer-grade die casting molds for appliances, electronics brackets, and more. The optimized mold cut scrap rates to below 10%, proving their versatility.

Conclusion

Mold design is the backbone of successful die casting, and mold flow analysis paired with smart tweaks is the shortcut to fewer defects. From venting to cooling, these five tips deliver results. Need to improve your die casting quality or cut production costs? We offer expert mold flow analysis and die casting services—reach out to learn more!