How to Choose the Right Process for Your Project

In metal manufacturing, two processes stand as pillars of production: die casting and sand casting. Like choosing between a precision espresso machine and handcrafted pour-over coffee, each method serves distinct purposes in the creation of metal components. This comprehensive guide will help you navigate this critical decision with professional insights and practical analogies.

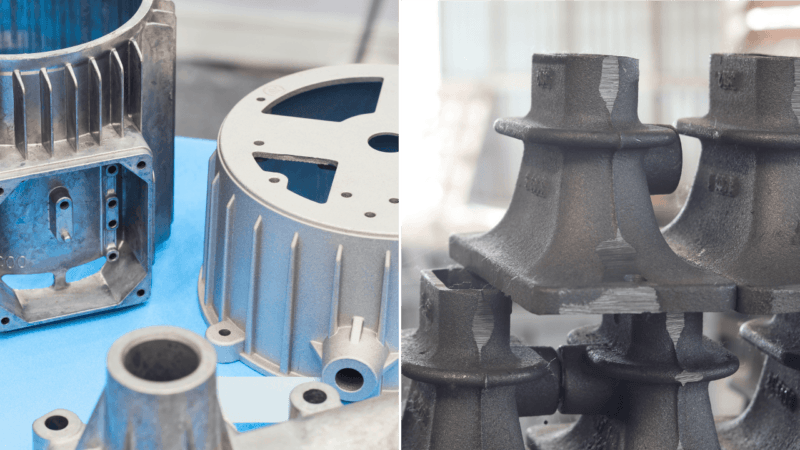

Fundamental Differences: Precision vs. Flexibility

Die Casting: The Industrial Coffee Machine

Imagine operating a specialty coffee franchise with automated equipment producing 200 identical lattes per hour. Die casting works similarly, using hardened steel molds under extreme pressure (up to 20,000 psi) to create precision components. This process delivers:

- Ultra-consistent results (±0.002" dimensional tolerance)

- Mirror-like surface finishes (Ra 32-64 µin)

- Rapid cycle times (30 seconds to 2 minutes per part)

Sand Casting: The Artisan Coffee Workshop

Picture a craft coffee shop where baristas hand-pour unique blends into reusable ceramic mugs. Sand casting operates on this principle, using disposable sand molds that allow:

- Unlimited design modifications

- Massive part capabilities (up to 200+ tons)

- Cost-effective prototyping

The critical distinction lies in mold durability and production philosophy. While die casting uses permanent tooling, sand casting employs temporary molds – a difference that fundamentally impacts their economic and technical applications.

Why Choose Die Casting? The Case for Precision Manufacturing

Technical Superiority in Mass Production

Modern die casting achieves what other processes can’t match in high-volume scenarios. Consider Bluetooth headphone cases requiring 0.1mm wall thicknesses and EMI shielding properties. The process delivers:

- 65% faster production vs. sand casting

- Near-net-shape components reducing machining costs

- Thin-wall capabilities down to 0.5mm for lightweighting

Economic Efficiency at Scale

While tooling costs range from \$15,000-\$100,000+, die casting becomes remarkably cost-effective through:

- Tool lifespan: 100,000-1,000,000+ cycles

- Multi-cavity molds: Producing 4-64 parts per cycle

- Automation compatibility: 24/7 production with robotic extraction

Real-World Application: Automotive manufacturers save 40% on transmission housings using multi-slide die casting machines, achieving 95% material utilization rates.

Material Innovation

Modern die casting alloys push performance boundaries:

- Silicon-aluminum alloys: 18% lighter than steel

- Magnesium alloys: 35% weight reduction vs. aluminum

- Zinc alloys: Superior EMI shielding for electronics

Why Choose Sand Casting? The Art of Flexible Production

Unmatched Design Freedom

Sand casting’s disposable molds enable:

- Instant design iterations: Modify patterns between pours

- Complex geometries: Internal channels, undercuts, and organic shapes

- Massive components: Wind turbine hubs exceeding 20-ton limits of die casting

Cost-Effective Low-Volume Production

For prototype runs of 1-500 units, sand casting offers:

- 90% lower tooling costs vs. die casting

- 24-hour mold fabrication using 3D printed sand

- Material versatility: From cast iron to cobalt alloys

Technical Trade-Offs

The flexibility comes with compromises:

- Surface finish: Requires 25-75µm post-processing

- Dimensional tolerance: Typically ±0.03"

- Production rate: 4-8 hours per mold cycle

Industry Example: Heavy equipment manufacturers use sand casting for custom excavator buckets, saving \$250,000 in tooling costs for 50-unit batches.

Head-to-Head Comparison: Key Decision Factors

| Parameter | Die Casting | Sand Casting |

|---|---|---|

| Tooling Cost | \$20k-\$500k+ | \$500-\$5k |

| Part Cost (10k units) | \$1.50-\$15 | \$8-\$80 |

| Minimum Wall Thickness | 0.5mm | 3mm |

| Max Part Size | 24"x36" (typical) | Unlimited |

| Surface Roughness | 32-64 µin | 300-500 µin |

| Lead Time | 8-16 weeks (tooling) | 2-4 weeks |

| Material Options | Non-ferrous alloys | All castable metals |

Strategic Selection Guide

Choose Die Casting When:

Volume Threshold Exceeds 5,000 Units

- Economic break-even typically occurs at 5k-10k units

- Automotive components: 100k+ annual volumes

Precision is Non-Negotiable

- Medical device components requiring FDA-level consistency

- Electronics enclosures with mating surface requirements

Thin-Wall Design is Critical

- Lightweight aerospace brackets

- Heat sink fins for thermal management

Opt for Sand Casting When:

Prototyping/Development Phase

- Functional prototypes for design validation

- Bridge tooling before committing to die casting

Oversized Components Needed

- Marine engine blocks

- Industrial machinery bases

Exotic Material Requirements

- High-temperature nickel superalloys

- Corrosion-resistant duplex steels

Cost-Benefit Analysis Framework

Use this decision matrix to evaluate your project:

Annual Volume

- <1,000 units → Sand casting

- 1k-50k units → Hybrid solutions

50k units → Die casting

Part Complexity

- Class A surfaces → Die casting

- Internal features → Sand casting

Timeline Constraints

- <8 weeks lead time → Sand casting

- Willing to invest in tooling → Die casting

Secondary Operations

- Minimal machining → Die casting

- Extensive finishing → Sand casting

Emerging Technologies Reshaping the Field

Die Casting Innovations

- Vacuum-assisted: Reduces porosity by 70%

- Squeeze casting: Enhances mechanical properties

- Mega-casting: Tesla’s 6000-ton Giga Press technology

Sand Casting Advancements

- Binder jetting: Digital sand molds with 0.1mm resolution

- Recyclable sands: 98% reclamation rates

- Hybrid patterns: Combine 3D printing with traditional methods

Partner Selection Criteria

When choosing a foundry partner, verify:

- Certifications: IATF 16949 for automotive, NADCAP for aerospace

- Material Expertise: Alloy-specific knowledge base

- Quality Systems: CMM capabilities, X-ray inspection

- Sustainability Practices: Scrap recycling programs

- Prototyping Support: Rapid pattern services

Conclusion: Precision vs. Flexibility

In today’s manufacturing landscape, the choice between die casting and sand casting isn’t binary but strategic. High-volume consumer products benefit from die casting’s relentless efficiency, while sand casting remains indispensable for heavy industry and R&D.

Final Recommendations:

- For automotive/electronics: Invest in die casting tooling

- For energy/construction: Leverage sand casting flexibility

- For emerging markets: Consider hybrid approaches

By aligning process capabilities with product lifecycle requirements, manufacturers can optimize both technical outcomes and financial performance. Remember – the right process choice today can yield 30-60% cost savings over a product’s lifetime.