When it comes to aluminum, picking between casting and extrusion can be confusing. Each method has strengths that make it suitable for different needs. Here’s a breakdown to help you choose the best process for your parts.

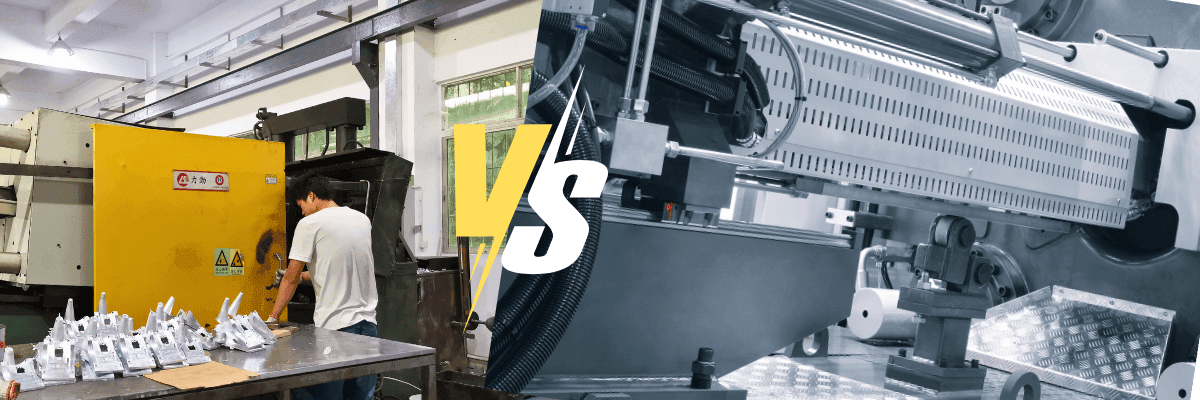

Overview of Die-Cast Aluminum

Die casting involves injecting molten aluminum into a mold under high pressure. This process creates complex, finely detailed parts with smooth surfaces and tight tolerances. Die-cast aluminum is commonly used for high-volume production of parts that require good dimensional accuracy and consistent quality.

Overview of Extruded Aluminum

Extrusion is a process where aluminum billets are heated and then forced through a die to form long shapes with uniform cross-sections. Extruded aluminum can be cut into various lengths, and the process allows for the creation of parts with a wide range of profiles and geometries. Unlike die casting, extrusion works better for parts with continuous shapes, such as bars, tubes, or profiles.

Key Differences Between Die-Cast and Extruded Aluminum

1. From a Process Perspective

| Feature | Die-Cast Aluminum | Extruded Aluminum |

|---|---|---|

| Metal State | Molten aluminum injected into mold | Heated aluminum pushed through die |

| Force Application | High-pressure injection | High pressure to push through die |

| Mold Design | Requires precise, complex molds | Simple molds, continuous cross-section |

| Processing Speed | Faster for high-volume production | Slower, limited by extrusion length |

| Tooling Cost | Higher tooling costs due to mold complexity | Lower tooling costs, simpler design |

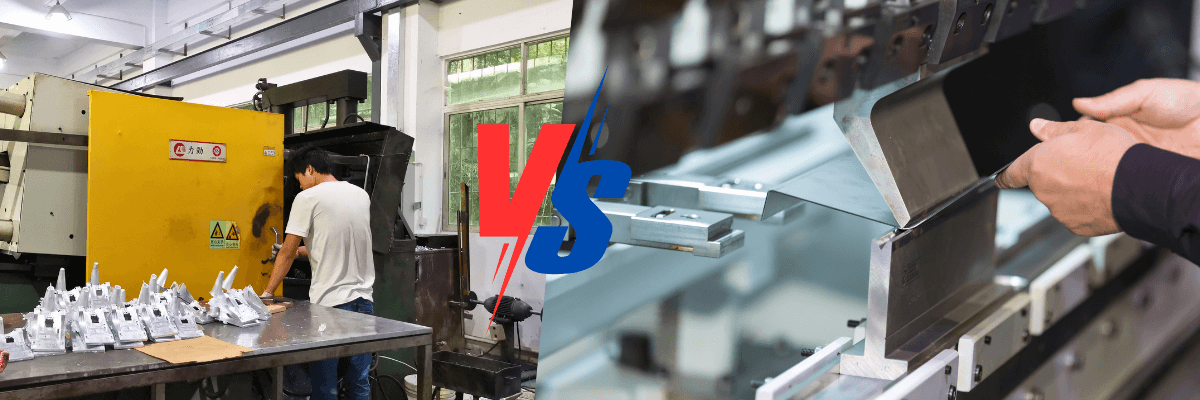

2. From a Workpiece Perspective

| Feature | Die-Cast Aluminum | Extruded Aluminum |

|---|---|---|

| Part Complexity | Ideal for complex, detailed shapes | Best for simple, continuous shapes |

| Strength | Lower strength due to casting defects | Higher strength, continuous grain structure |

| Surface Finish | Smooth, refined surface | Rougher surface, may require additional processing |

| Precision | High precision and dimensional accuracy | Moderate precision, can vary along length |

| Production Volume | Best for high-volume production | Ideal for both low and high-volume production |

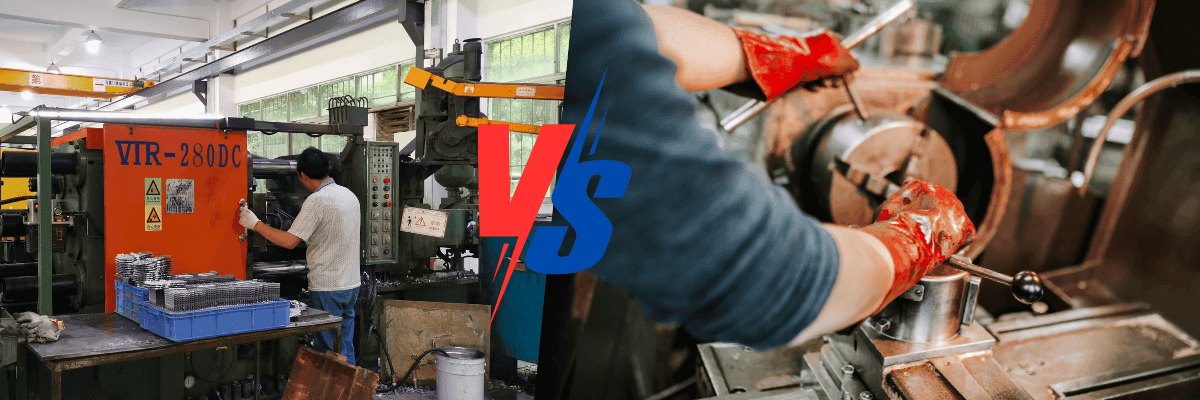

Advantages of Die-Cast Aluminum

- Complex Shapes: Die casting excels at producing parts with intricate designs, making it ideal for products like housings and enclosures in electronics and automotive industries.

- Precision: Die-cast parts can be made with tight tolerances and minimal need for secondary finishing.

- Smooth Surface: The process results in smooth surfaces that often need little or no additional finishing.

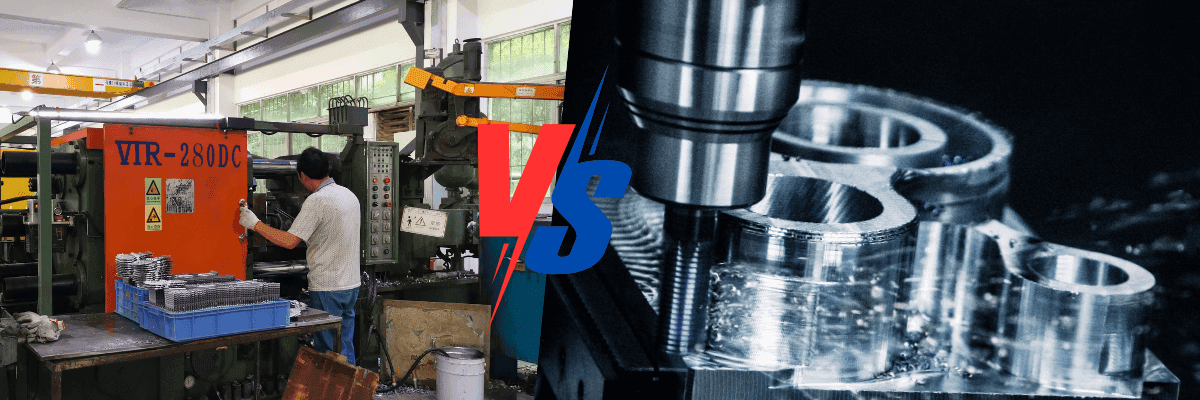

Advantages of Extruded Aluminum

- Higher Strength: The extrusion process aligns the metal’s grain structure, resulting in stronger parts.

- Cost-Effective for Certain Shapes: Extrusion is generally more cost-effective for simple, continuous shapes like rods, tubes, and frames.

- Customization: The extrusion process allows for significant design flexibility, with the ability to create complex cross-sectional profiles.

Applications of Die-Cast Aluminum

Die-cast aluminum is widely used in applications requiring high-volume production of complex and detailed parts. These applications include automotive components, electronics housings, and various consumer products.

Applications of Extruded Aluminum

Extruded aluminum is commonly used for structural components, such as frames, rails, and supports in industries like construction, transportation, and architecture.

Conclusion

The choice between die-cast and extruded aluminum depends on factors like part complexity, strength requirements, production volume, and cost considerations. Die casting is perfect for intricate, high-precision parts with a smooth finish, while extrusion is ideal for simpler, continuous shapes with higher strength.

Are you looking for complex, high-precision parts, or do you need stronger, simpler components for your project?

Leave a Reply