Case study

Resolving Porosity Defects in Aluminum Die Casting

Front Oil Seal Flange Case Study Introduction In automotive manufacturing, aluminum die casting delivers precision components like the…

Post-Processing and Fixture Design for Integrated Motor Endcover

The integrated motor end cover and gearbox die-casting packs strength and efficiency, but its raw IT10 precision falls…

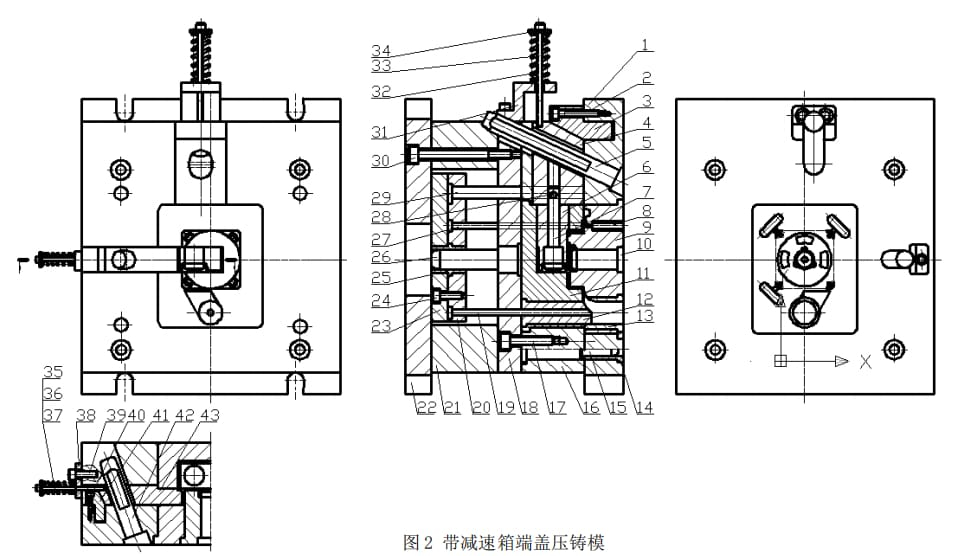

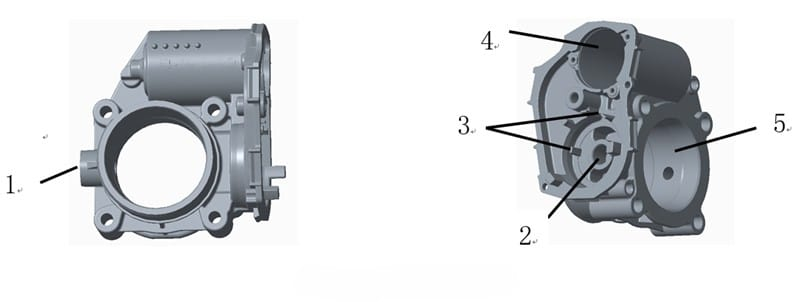

Integrated Motor Endcover Die-Casting Mold Design

Integrating a motor end cover with a gearbox into a single aluminum alloy die-cast part transforms small, low-speed…

Clamping Force in Casting Mold Design Guidelines

How to Master Clamping Force in Casting Mold Design: A Practical Guide In die-casting, clamping force—the grip a…

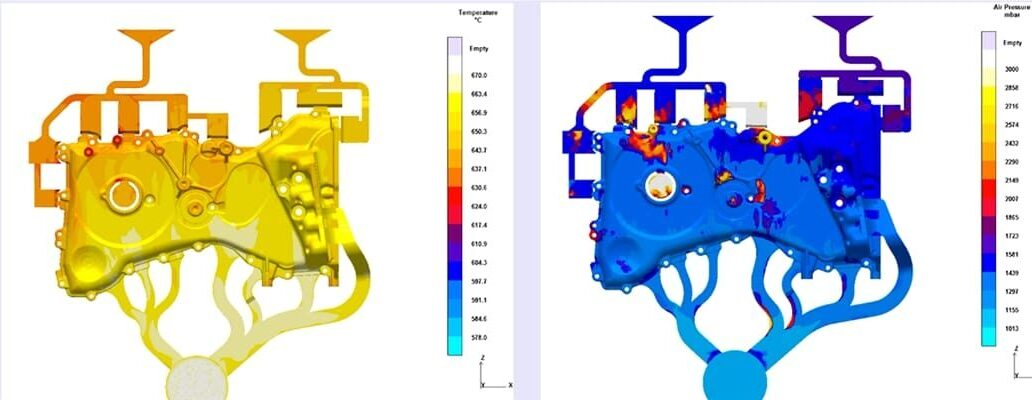

Optimizing Die-Casting for Aluminum Engine Front Cover

Optimizing Die-Casting for Aluminum Alloy Engine Front Covers: A Practical Case Study The automotive industry’s drive for lighter…

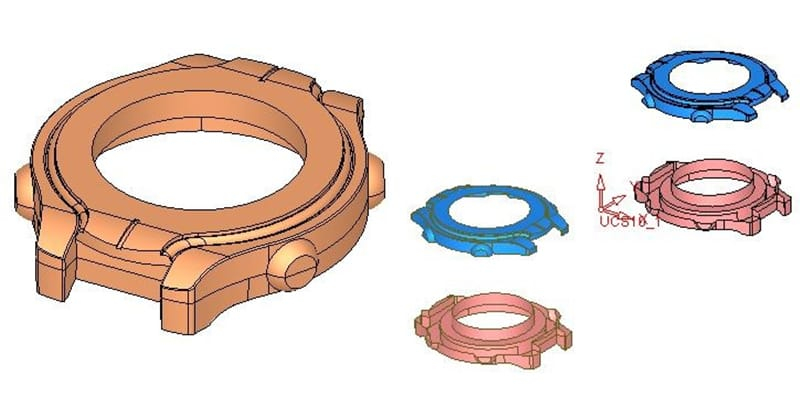

Mold Design Strategies For Smartwatch Bezel

Exploring Mold Design Strategies: A Smartwatch Bezel Case Study Smartwatch bezels are more than just stylish—they demand precision…

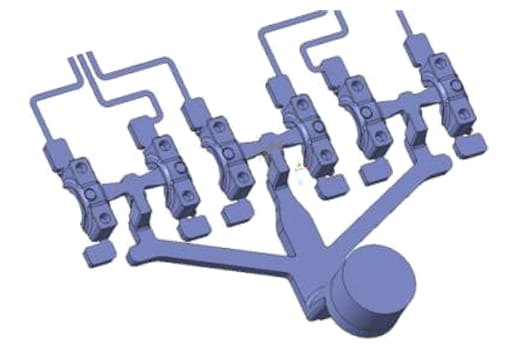

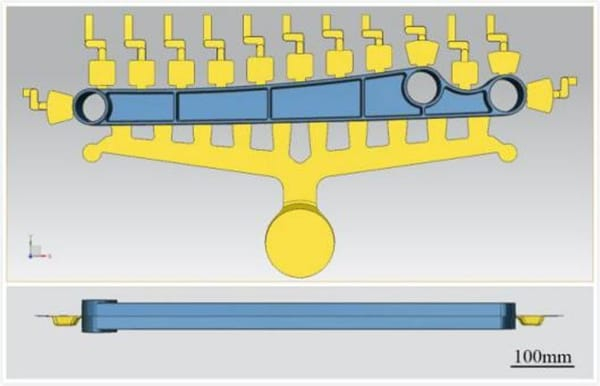

A Multi-Cavity Mold Design for Small Brackets

Die-Casting Porosity Solutions: Developing a Multi-Cavity Mold for Small Brackets Principles of Small Bracket Die Casting Small brackets…

Optimize Low-Speed Parameters in High-Pressure Die-Casting

How to Optimize Low-Speed Parameters in High-Pressure Die-Casting for EV Oil Coolers to Reduce Defects Principles: Low-Speed Tuning…

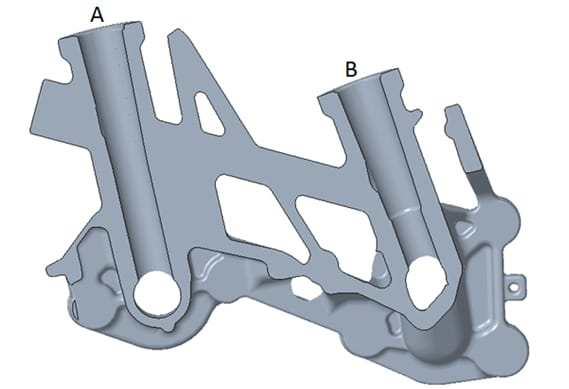

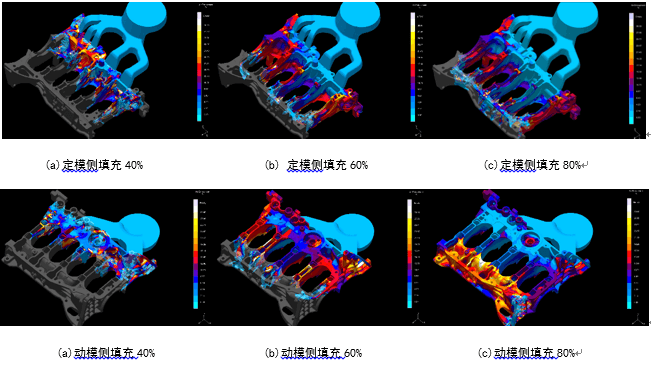

Cross-Runner Design for EV Shock Tower Molds

How to Optimize Cross-Runner Design for EV Shock Tower Die-Casting Molds Using Flow Simulation Principles: Cross-Runner Design Boosts…

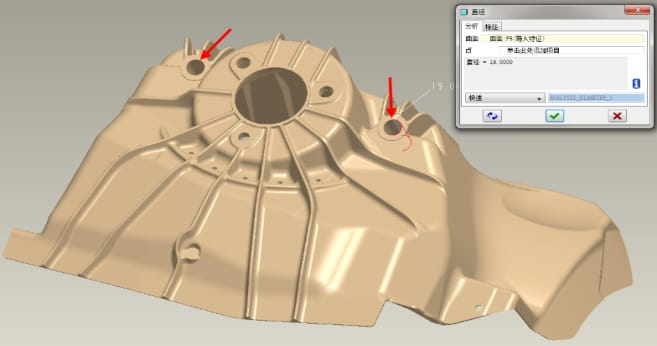

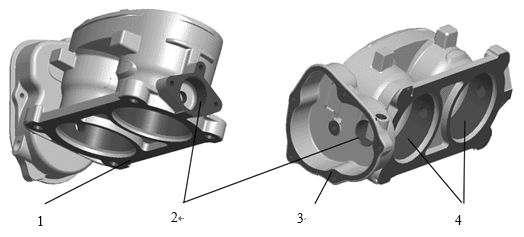

Porosity and Material Detachment in Dual-Chamber Throttle Body

How to Address Porosity and Material Detachment in Dual-Chamber Throttle Body Die Casting Principles: Casting Defects Impact Product…

Fix Vacuum Valve Failures in Die Casting Exhaust Systems

How to Fix Vacuum Valve Failures in Aluminum Die Casting Exhaust Systems Principles: Vacuum Die Casting for Enhanced…

5 Tips for Die-Casting Mold Design

5 Practical Tips for Optimizing Die Casting Mold Design The success of die casting hinges on mold design,…

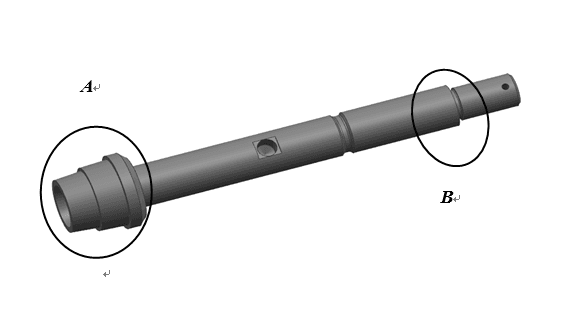

Die Casting Process Parameters for Automotive Rear Trailing Arm

Optimizing Die Casting Process Parameters for Automotive Rear Trailing Arms Principles: Die Casting Enables Lightweight Suspension Components The…

Mold Design for Aluminum Lower Cylinder Block

Optimized Die Casting Mold Design for Aluminum Alloy Lower Cylinder Block in Automotive Engines Principles: The Critical Role…

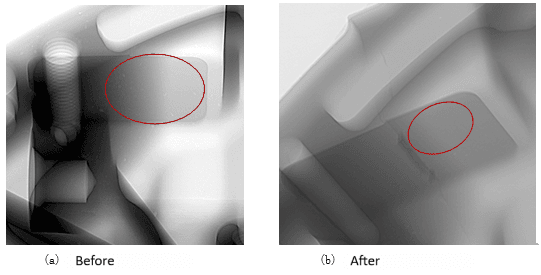

Porosity and Slag in Die-Casting Aluminum Shock Tower

Porosity and Slag Issues in Vacuum Die-Cast Aluminum Shock Towers: Analysis and Solutions Problem: Shock Tower Mechanical Properties…

Porosity in Aluminum Engine Block

Porosity in Aluminum Alloy Die-Casting Engine Blocks: Causes and Solutions Porosity Formation Principles Porosity in aluminum alloy die…

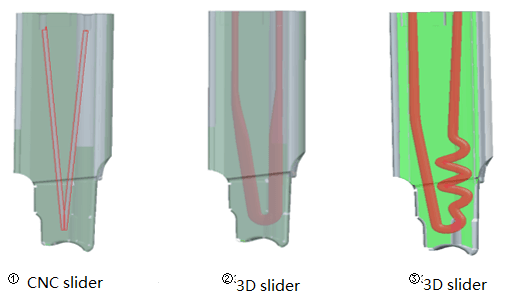

3D Printing Die Casting Insert Solutions

Shrinkage Porosity Due to Die Casting Insert Aging: Solutions with 3D Printing The Role and Principle of Die…

Shrinkage Porosity in Aluminum Die Casting

Solution for Shrinkage Porosity in Aluminum Alloy Die Casting Engine Crankcase Shrinkage porosity is a common internal defect…

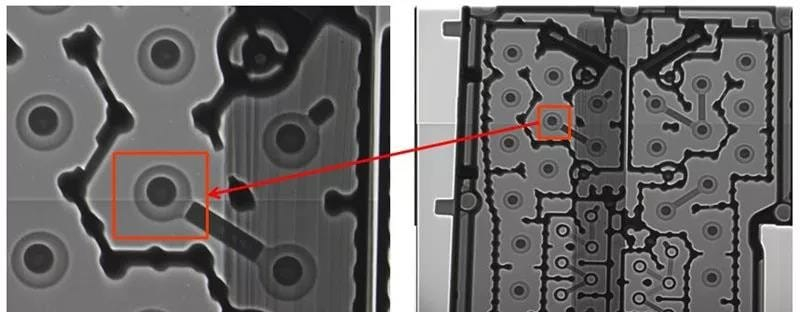

Porosity Challenges in Aluminum Die-Cast Filters

Addressing Porosity Challenges in Aluminum Alloy Die-Cast Filters with CAE Analysis Abstract As aluminum alloy die casting trends…

Fixing Undercasting and Porosity in Die Casting

Fixing Undercasting and Porosity in Die Casting with Mold Flow Analysis How Mold Flow Analysis Reduces Die Casting…