How to Master Clamping Force in Casting Mold Design: A Practical Guide

In die-casting, clamping force—the grip a cooling casting exerts on the mold—can make or break production. As alloys like aluminum and magnesium solidify, this force shifts dynamically, sometimes locking parts in place or even damaging molds if mishandled. This guide dives into the mechanics of clamping force, using an ADC12 aluminum alloy casting as a case study. We’ll explore how to optimize mold design through thermal expansion and shrinkage rates, and share a field-tested fix for ejection woes tied to temperature swings.

Problem: Clamping Force Complications

Take an ADC12 aluminum alloy casting with a nominal size of 40 mm. As it cools from a molten 580°C to an ejection temperature of 350-400°C, the mold (made of 8407 steel) tracks along at 280-300°C. Early runs hit snags:

- Ejection Struggles: Post-cooling, the casting shrank, gripping the mold too tightly for ejector pins to budge.

- Shrinkage Rate Guesswork: Design handbooks suggest a 0.4%-0.7% shrinkage rate, but temperature fluctuations threw off predictions, amplifying clamping force.

- Defect Risks: Excessive force risked piercing the casting or wearing down the mold.

The culprit? A dynamic dance between the casting’s and mold’s thermal expansion rates, shifting clamping force in ways standard designs didn’t account for. It was time to dig deeper.

Approach: Taming Clamping Force with Data

To get a handle on this, the team zeroed in on thermal expansion coefficients and shrinkage rates, crafting a strategy rooted in real-world conditions:

- Thermal Expansion Mapping: Compare how castings (ADC12, A380, AM50) and mold steel (8407) expand with temperature.

- Shrinkage Rate Precision: Calculate ideal rates based on ejection-point temperature differences.

- Temperature-Based Fixes: Adjust casting heat to ease ejection when clamping force spikes.

By blending production stats with simulations, the approach aimed to align design with reality.

Methods: Solutions That Stick

Decoding Thermal Expansion

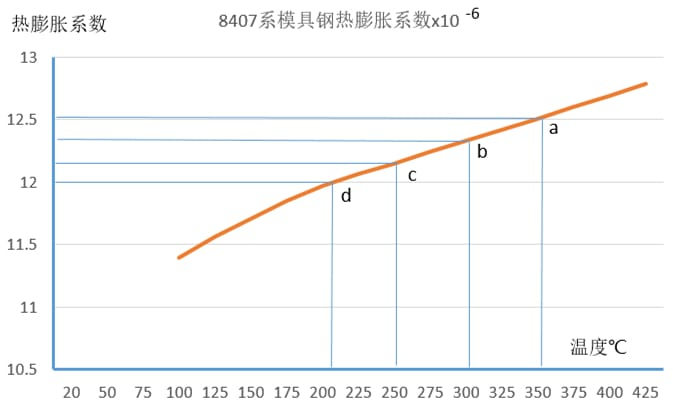

Clamping force hinges on how materials stretch and shrink with heat. For ADC12, the thermal expansion coefficient jumps from 23.4×10⁻⁶°C⁻¹ at 350°C to 23.8×10⁻⁶°C⁻¹ at 400°C; meanwhile, 8407 mold steel moves from 12.27×10⁻⁶°C⁻¹ at 280°C to 12.33×10⁻⁶°C⁻¹ at 300°C. Table 1 lays it out:

| Casting Temp (°C) | ADC12 r (×10⁻⁶) | A380 r (×10⁻⁶) | AM50 r (×10⁻⁶) | Mold Temp (°C) | 8407 r (×10⁻⁶) | ADC12 Casting Size (mm) | ADC12 Mold Size (mm) | A380 Casting Size (mm) | A380 Mold Size (mm) | AM50 Casting Size (mm) | AM50 Mold Size (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 0 | 0 | 0 | 20 | 0 | 40 | 40.2 | 40 | 40.24 | 40 | 40.28 |

| 350 | 23.4 | 23.9 | 26.5 | 280 | 12.27 | 40.31 | 40.33 | 40.32 | 40.37 | 40.35 | 40.41 |

| 400 | 23.8 | 24.3 | 27 | 300 | 12.33 | 40.36 | 40.34 | 40.37 | 40.38 | 40.41 | 40.42 |

| Recommended | |||||||||||

| 370 | 23.6 | 24.1 | 26.7 | 290 | 12.3 | – | – | – | – | – | – |

Mold size uses the formula D₂ = D₁[1 + r(t₂ – t₁)], with shrinkage rate a = (mold size/casting size) – 1. Recommended values (casting 370°C, mold 290°C) anchor the design.

Alt: Die-casting thermal expansion curves for ADC12 and 8407 mold steel

Nailing Shrinkage Rates

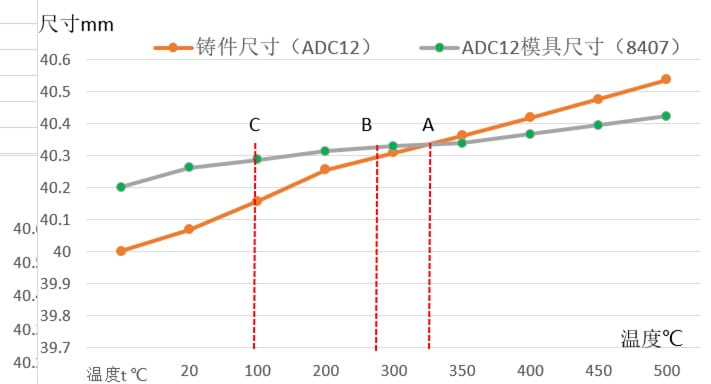

At ejection, ADC12 hits ~370°C (23.6×10⁻⁶°C⁻¹), with the mold at 290°C (12.3×10⁻⁶°C⁻¹). The casting measures 40.31 mm, the mold 40.33 mm—yielding a 0.005 shrinkage rate. A380 (24.1×10⁻⁶°C⁻¹) and AM50 (26.7×10⁻⁶°C⁻¹) adjust to 0.006 and 0.007, reflecting their higher silicon-driven expansion. These rates ensure the mold stays just ahead of the casting’s size at ejection, easing release.

Fixing Ejection Hiccups

When production paused, casting temperature dropped to ~300°C (40.26 mm), dipping below the mold’s 40.31 mm at 250°C—clamping force soared. The fix? Bake the casting with natural gas to 370°C (40.36 mm) or 400°C (40.37 mm), surpassing the mold’s 40.34 mm at 300°C. This heat boost cuts clamping force, letting pins do their job. Bake-and-try ejection proved quick and effective, sidestepping costly mold disassembly.

Alt: Die-casting size changes for ADC12 casting and 8407 mold with temperature

Why It Works

The magic lies in the slopes: castings expand faster than molds (e.g., ADC12’s 23.6 vs. 8407’s 12.3 at 370°C/290°C). Their sizes cross at a sweet spot (~370°C/290°C). Drop below it (C zone), and the casting shrinks tighter; heat past it (B or A zones), and it swells free. Overheating risks strength loss, so moderation’s key.

Conclusion: Clamping Force, Conquered

Clamping force stems from the thermal tug-of-war between casting and mold—a dance defined by their expansion slopes. Nail the shrinkage rate (0.005 for ADC12, 0.006 for A380, 0.007 for AM50) at the 370°C/290°C sweet spot, and ejection smooths out. Hit a snag? A quick bake to nudge the casting’s size past the mold’s slashes clamping force fast. This blend of design precision and shop-floor savvy offers a playbook for mastering die-casting molds.

Key Parameters Table

| Parameter | ADC12 Value | A380 Value | AM50 Value |

|---|---|---|---|

| Ejection Temp (°C) | 370 | 370 | 370 |

| Mold Temp (°C) | 290 | 290 | 290 |

| Thermal Expansion (×10⁻⁶°C⁻¹) | 23.6 | 24.1 | 26.7 |

| Mold Expansion (×10⁻⁶°C⁻¹) | 12.3 | 12.3 | 12.3 |

| Casting Size (mm) | 40.31 | 40.32 | 40.35 |

| Mold Size (mm) | 40.33 | 40.37 | 40.41 |

| Shrinkage Rate | 0.005 | 0.006 | 0.007 |