Shrinkage Porosity Due to Die Casting Insert Aging: Solutions with 3D Printing

The Role and Principle of Die Casting Inserts

Die casting inserts are critical components embedded in molds, shaping complex areas of castings while providing localized cooling. They work by channeling heat away through internal water passages, controlling solidification to ensure quality. However, as production cycles increase, insert surfaces age, weakening cooling efficiency and risking defects.

Problem Description

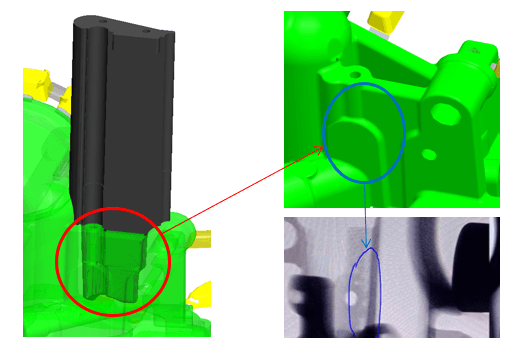

In aluminum alloy die casting, aging inserts often compromise cooling, causing shrinkage porosity in thick-walled casting zones. For example, one product showed shrinkage defects due to reduced insert performance, with leak test scrap rates soaring above 30%. To maintain quality, inserts were typically replaced after 20,000-30,000 cycles, driving up costs. Figure 1 illustrates a typical shrinkage case linked to poor cooling.

Solution Approach

Shrinkage stems from reduced heat transfer as inserts age, lowering the interface heat transfer coefficient between insert and casting. This traps heat, disrupting uniform solidification. The goal is to enhance insert cooling to counter aging effects. Traditional CNC-machined cooling channels have limited flexibility, so a shift to advanced cooling designs was explored.

Solution Methods

Simulation Validation

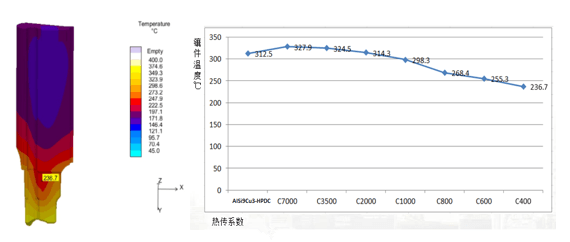

Simulations tested the impact of aging by reducing the interface heat transfer coefficient under constant conditions. Results (Figure 2) confirmed that lower coefficients increased insert temperatures, validating cooling as the root cause of shrinkage.

Alt: Temperature simulation showing insert temperature rise as the heat transfer coefficient decreases.

3D Printing for Enhanced Cooling

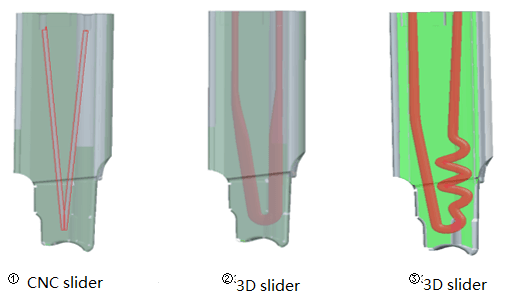

Conventional CNC cooling channels are linear, with small heat dissipation areas and limited efficiency. Using 3D printing, conformal cooling channels were designed to follow the insert’s contours, expanding surface area (Figure 3). Simulations (Figure 4) showed 3D-printed inserts stayed ~50°C cooler than traditional ones, even as aging progressed. Design #3, with the largest cooling area, excelled in early cycles.

Alt: Comparison of traditional CNC vs. 3D-printed cooling channel designs, highlighting conformal cooling benefits.

Implementation and Results

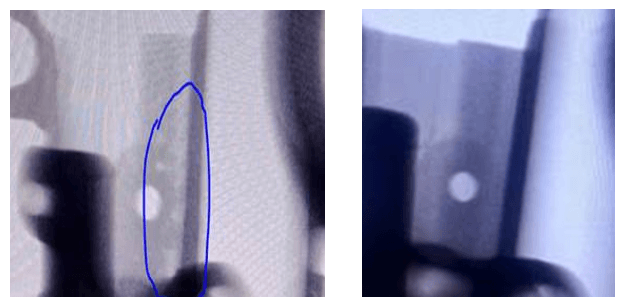

Switching to 3D-printed inserts slashed leak test scrap rates to below 2%, with shrinkage defects nearly eliminated (Figure 5). Insert lifespan also jumped from 20,000-30,000 to 50,000-60,000 cycles, proving the upgrade’s success.

Alt: Pre- and post-improvement defect inspection results, showing reduced shrinkage porosity.

Conclusion

Aging inserts weaken cooling, triggering shrinkage porosity and high scrap rates. Simulations pinpointed the cause, leading to a 3D printing solution that optimized cooling channels. This cut scrap rates from 30% to 2% and doubled insert life, boosting efficiency and cost savings. The approach offers a practical fix for similar die casting challenges.