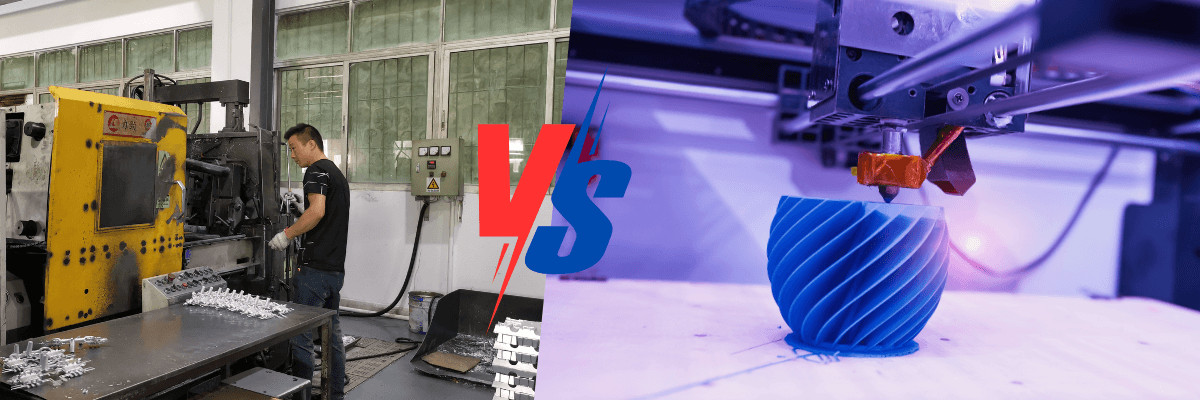

In manufacturing, choosing the right process is crucial for production efficiency and cost-effectiveness. Die casting and 3D printing are two distinct methods, each with its own set of materials, techniques, and applications. Understanding the advantages and limitations of both will help you make an informed decision for your project.

Differences in Die Casting vs 3D Printing

Die casting involves injecting molten metal into a mold under high pressure to create complex parts (think of making shaped chocolate—liquid metal + mold shaping); 3D printing, on the other hand, builds parts by layering material according to a digital design (more like building with Lego—digital file + layer-by-layer construction). The key differences lie in the materials used, production method, and final part characteristics.

Part Comparison

| Process | Die Casting | 3D Printing |

|---|---|---|

| Materials | Primarily aluminum, zinc, and magnesium alloys. | A variety of metals, plastics, ceramics, depending on printer type. |

| Part Complexity | Suitable for manufacturing complex shapes with fine details. | Ideal for intricate designs, especially with internal features. |

| Production Volume | Best for high-volume runs with reduced per-part cost. | Suitable for low-volume, prototyping, and customized parts. |

| Strength & Durability | High tensile and compressive strength, suitable for structural parts. | Strength varies, usually lower than die casting, better for non-structural components. |

| Precision & Surface Finish | High precision (±0.05mm), better surface finish options. | Moderate precision, rougher surface that often requires post-processing. |

| Cost | High initial tooling cost, but lower per-part cost for large runs. | Lower initial cost, higher per-part cost, ideal for small batches. |

| Industries | Automotive, aerospace, electronics, and industries requiring high precision. | Ideal for small batch, customized, and prototype production, used in aerospace, medical, and automotive sectors. |

Surface Finishing Comparison

Both die casting and 3D printing have distinct capabilities for surface treatment. The table below provides a quick overview of what each process can achieve.

| Surface Treatment/Texture | Die Casting | 3D Printing | Explanation |

|---|---|---|---|

| Gloss Finish | ✅ | ❌ | Die casting can achieve very smooth surfaces, ideal for high-end appearance; 3D printing typically leaves visible print layers. |

| Matte Finish | ✅ | ✅ | Both processes can achieve a matte finish, though die casting offers a more uniform result. |

| Brushed Effect | ✅ | ✅ | Both can produce a brushed finish, but 3D printing typically does not achieve the fine details of die casting. |

| Texture Treatment | ✅ | ✅ | Both can handle textured finishes, but die casting is better for intricate patterns, while 3D printing works for simpler designs. |

| Electroplating | ✅ | ✅ | Both can be electroplated, but 3D printed parts may require additional post-processing due to surface roughness. |

| Spray Coating | ✅ | ✅ | Both can be spray coated, but 3D printing may result in uneven coverage due to its rougher surface. |

| Anodizing | ✅ | ❌ | Die casting is suitable for anodizing, especially for aluminum; 3D printing does not typically support this treatment. |

| Electropolishing | ✅ | ❌ | Die casting can undergo electropolishing to enhance surface finish; 3D printing cannot support this process. |

Conclusion

Die casting and 3D printing both offer unique advantages. Die casting excels in high-volume production of complex parts with superior strength and surface finish, while 3D printing is ideal for low-volume, highly customized designs, especially in prototyping.

Need help choosing the right process for your project? Contact us today, and we’ll guide you in selecting the best option based on your specific needs!

Leave a Reply