Fixing Undercasting and Porosity in Die Casting with Mold Flow Analysis

How Mold Flow Analysis Reduces Die Casting Scrap Rates by 38%

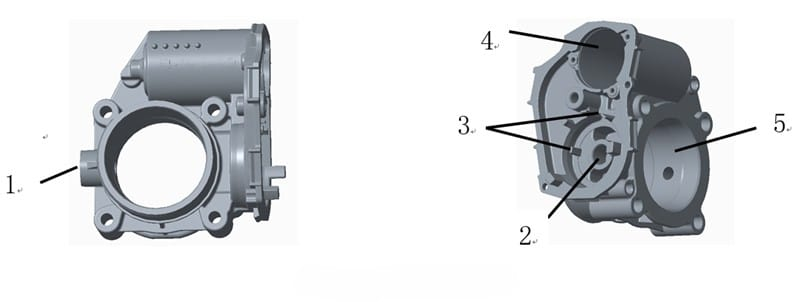

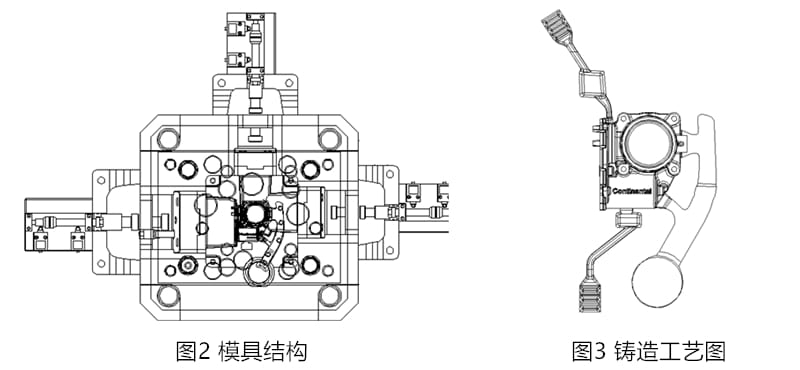

In the consumer-grade die casting industry, scrap rates are a critical factor affecting costs and customer satisfaction. Take this throttle valve body as an example: its complex deep-cavity structure and stringent quality requirements (e.g., porosity must not exceed 0.4mm) often result in scrap rates as high as 48%. Fortunately, mold flow analysis offers an advanced solution to identify issues and optimize mold design. This article explores a real-world case where mold flow analysis slashed the scrap rate from 48.52% to below 10%, providing actionable insights for your die casting projects.

Case Study: Challenges with the Throttle Valve Body

The B15B throttle valve body is a typical consumer-grade die casting part, measuring 107mm × 103mm × 63mm with wall thicknesses ranging from 1.7mm to 5mm and a weight of approximately 400g. Used in automotive electronic fuel injection systems, it demands flawless appearance and internal quality. However, production revealed two primary scrap issues:

- Blank Defects: Undercasting in the gearbox-side limit pins (1.3mm diameter, 9mm height) and surrounding areas.

- Post-Machining Scrap: Excessive porosity in the air intake ring and inner gate base.

These issues stemmed from mold design and process limitations, with traditional adjustments (e.g., injection speed) proving ineffective.Applying Mold Flow Analysis

Mold flow analysis simulates molten alloy flow, cooling, and venting, pinpointing defect causes. Here’s how it addressed the B15B issues:

- Tackling Undercasting

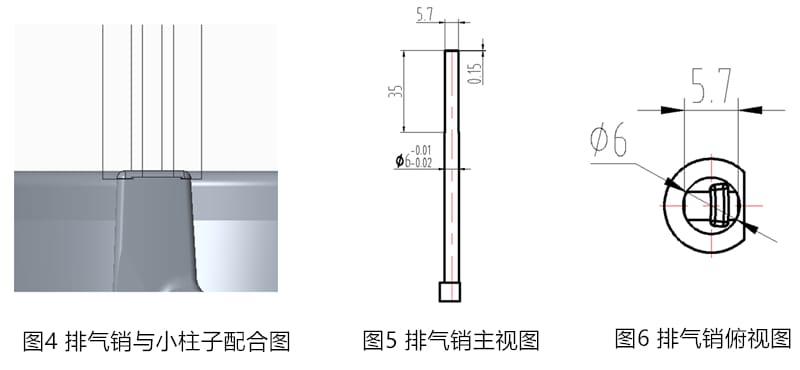

- Limit Pin Undercasting: Analysis showed trapped gas in the deep cavity prevented filling. A vent pin (6mm diameter, flattened 0.15-0.2mm on sides) was added near the pin to release trapped air.

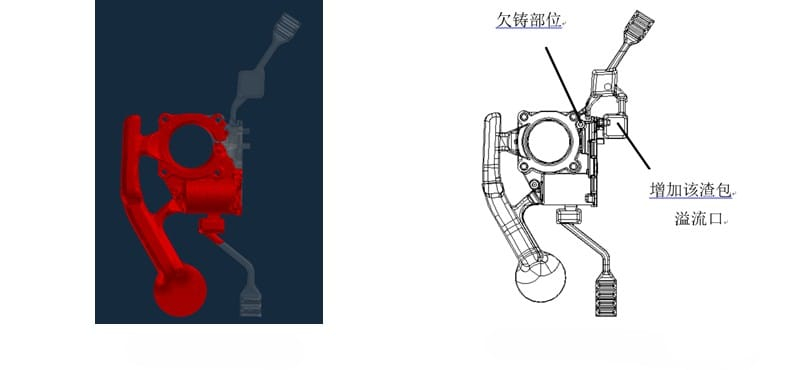

- Peripheral Undercasting: Simulations revealed undercasting at the fill end due to absent overflow systems. Adding a slag trap and overflow vent expelled cold material and gases, improving fill completeness.

- Limit Pin Undercasting: Analysis showed trapped gas in the deep cavity prevented filling. A vent pin (6mm diameter, flattened 0.15-0.2mm on sides) was added near the pin to release trapped air.

Reducing Porosity

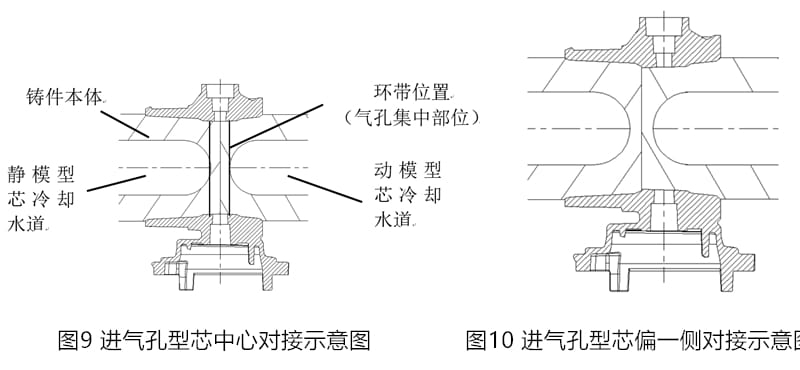

Air Intake Ring Porosity: Porosity clustered near core joints. Enhanced cooling was implemented by extending the moving core’s water channel to the ring area, creating a chill layer to minimize gas entrapment.

Inner Gate Porosity: The original gate slope of 27° fell below the recommended 30°-45°. Adjusting it to 35° improved alloy flow, reducing porosity.

Results and Takeaways

With these optimizations, the B15B’s scrap rate dropped from 48.52% to below 10%, saving significant material and machining costs. This demonstrates mold flow analysis as a powerful tool for boosting die casting efficiency, applicable to complex consumer parts like appliances or electronics.

Mold flow analysis transforms die casting from trial-and-error to precision optimization. Whether you’re producing automotive components or consumer electronics housings, investing in this technology can drastically cut scrap rates and enhance competitiveness. Looking for reliable die casting services? Our expert team offers tailored solutions—contact us today for more details!