The integrated motor end cover and gearbox die-casting packs strength and efficiency, but its raw IT10 precision falls short of the IT6 needed for bearing bores and mounting lips. This follow-up dives into the post-processing of this aluminum alloy casting (Figure 7), tackling its quirky shape and orthogonal bores with a milling fixture that’s accurate, sturdy, and flips like a pro.

Problem: Precision vs. Complexity

This casting—end cover fused with a gearbox—handles a worm shaft dropping 960 RPM to 60 RPM via a turbine. But its irregular shape and two perpendicular bearing bores (30 mm diameter, 9 mm deep) posed headaches:

- Precision Gap: Die-casting hit IT10; bearings and lips needed IT6.

- Orthogonal Bores: Lathe setups couldn’t cut both in one go—multiple clamps killed perpendicularity.

- Thin-Wall Woes: Clamping risked warping the delicate frame.

The complexity clashed with tight tolerances—standard machining wouldn’t cut it.

Approach: Milling and Fixture Blueprint

To bridge the gap, the team pivoted to milling with a custom fixture:

- Process Pick: Weigh lathe vs. mill for best fit.

- Fixture Focus: Lock in positioning and clamping without distortion.

- Flip Factor: Nail two bores in one setup.

The aim? A fixture that’s simple, precise, and gets the job done fast.

Methods: Milling Mastery Unleashed

The Milling Plan

With 0.5 mm left for machining, milling on a vertical center took the lead:

- End Cover: Lip goes from 98.5 mm to 99±0.025 mm; bore from 29.5 mm (8.5 mm deep) to 30±0.025 mm (9 mm deep).

- Gearbox: Bore matches the end cover specs.

Lathes flunked—two setups tanked accuracy. Milling with a fixture aced it in one.

Fixture Breakdown

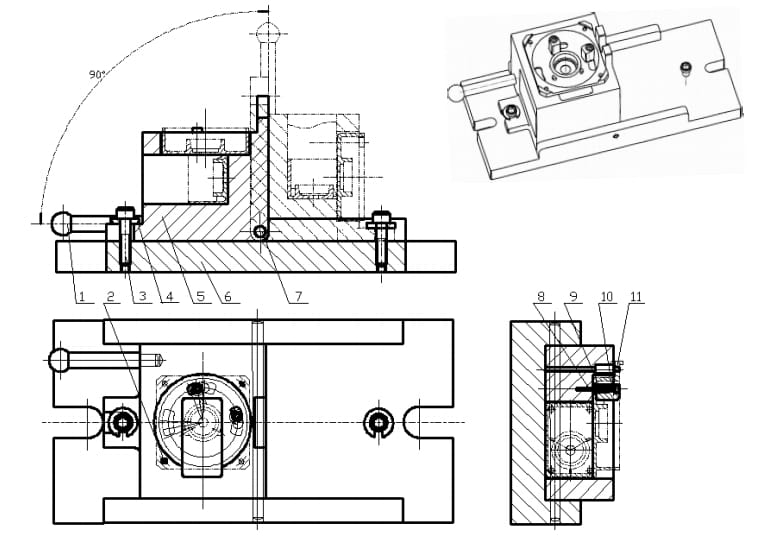

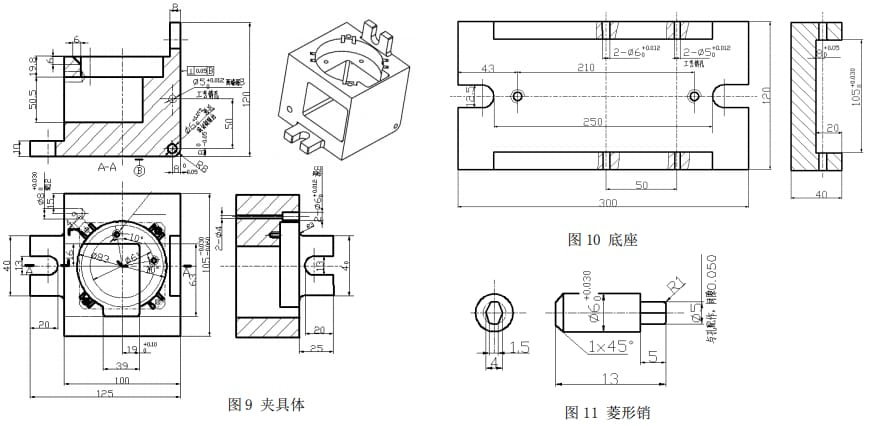

The fixture (Figure 8) features a clamp body, base, pivot shaft, pins, and swiveling clamps:

- Positioning: Two 5 mm mounting holes snag a round pin and a diamond pin, locking rotation.

- Clamping: Swivel blocks with screws and springs secure the part; they flip to cooling slots for release.

- Flipping: The clamp body pivots 0°-90° on a 60±0.012 mm shaft, locked by a base screw and washer.

Alt: Milling fixture for die-cast motor end cover and gearbox

How It Runs

- Lock It: Slot a washer, tighten the base screw—clamp’s set.

- Clamp Up: Slip the casting onto pins, swivel blocks in, tighten screws.

- Mill End Cover: At 0°, cut the lip and bore.

- Flip and Mill: Loosen, pivot to 90°, relock—hit the gearbox bore.

- Pop Off: Loosen blocks, swing to slots, lift free.

Wire EDM ensures the shaft hole’s 80-0.05 mm precision, keeping flips spot-on.

Alt: Milling fixture processing orthogonal bores on die-cast part

Standout Features

- Pin Power: Two-pin setup leverages casting consistency, dodging deformation.

- 90° Flip: One clamp, two bores—perpendicularity stays under 0.05 mm.

- Quick Tricks: Washers and springs speed swaps without fuss.

Why It Works

The fixture’s flip nails orthogonal cuts without re-clamping. Precision grinding and EDM keep the pivot true, while gentle clamping protects thin walls. It’s elegant and effective.

Conclusion: Precision, Meet Efficiency

This milling fixture lifts the die-cast part from IT10 to IT6, nailing bearing and lip specs with one setup. Its smart pins and swivel design conquer complexity, offering a slick fix for post-processing intricate castings. Curious about how this part starts life? Read “Mold Design for Integrated Motor End Cover and Gearbox Die-Casting” to see the mold magic behind it.

Key Specs Table

| Feature | Detail |

|---|---|

| Raw Precision | IT10 |

| Target Precision | IT6 |

| Bore Size | 30±0.025 mm, 9 mm deep |

| Lip Size | 99±0.025 mm |

| Flip Angle | 0°-90° |