Solution for Shrinkage Porosity in Aluminum Alloy Die Casting Engine Crankcase

Shrinkage porosity is a common internal defect in aluminum alloy die casting, often found in thick-walled areas or hot spots. While minor shrinkage may not affect general parts, it’s unacceptable in critical components like engine oil passages, where it risks leaks. This article explores how shrinkage forms, using a real-world engine crankcase example to show practical fixes.

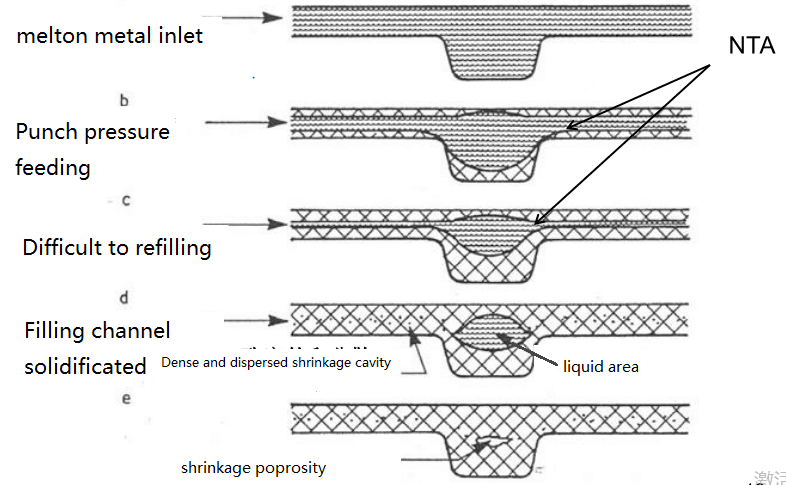

What Causes Shrinkage Porosity?

Shrinkage porosity occurs when molten aluminum solidifies without enough material to fill the shrinking volume. Key causes include:

- Uneven Mold Temperature: Poor gradients lead to uneven solidification.

- Insufficient Metal Supply: Thin cakes or low pressure limit compensation.

- Hot Spots: Thick walls or sharp corners trap heat, delaying solidification.

- Narrow Gates: Small inner gates solidify early, blocking pressure transfer.

- Low Pressure: Weak casting pressure fails to fill voids.

In short, if the mold cools unevenly or pressure can’t reach all areas, shrinkage pores form.

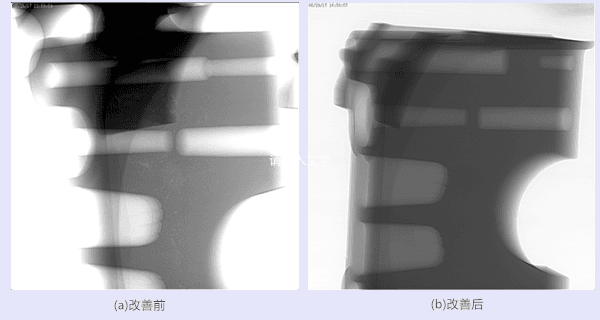

Case Study: Engine Crankcase Shrinkage

An aluminum alloy engine crankcase (ADC12, 6.3kg), cast on a Buhler 28,000kN machine, showed shrinkage porosity near the second crankshaft bearing oil passage—8mm from the hole. X-rays revealed an elliptical pore, 10mm wide, in a 22mm-thick wall area with no cooling near the oil plug, raising the mold temperature. This posed an oil leakage risk, with a 5% scrap rate in 2017.

Alt: engine crankcase showing shrinkage porosity near the oil passage before optimization.

How to Fix It?

Fixing shrinkage required a step-by-step approach, targeting mold design, cooling, and pressure.

Step 1: Adjust Process Parameters

Initial checks showed a 4mm gate, 40m/s pour speed, 25mm cake, and 60MPa pressure—seemingly adequate. Suspecting weak pressure compensation, we:

- Increased pressure to 90MPa.

- Thickened the cake to 30mm.

Small-batch tests dropped the scrap rate from 5% to 4.8%—a minor improvement, suggesting process tweaks weren’t enough.

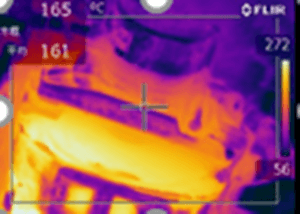

Step 2: Optimize Mold Cooling

Thick walls (22.6mm) and high mold heat (272°C post-spray) hinted at uneven cooling. We:

- Deepened cooling channels from 20mm to 12mm from the surface.

- Lowered pouring temperature from 675°C to 645°C.

- Extended spray time at the defect spot from 2s to 3s.

Mold temperature fell to 200°C, reducing the scrap rate to 4%. Better, but not solved.

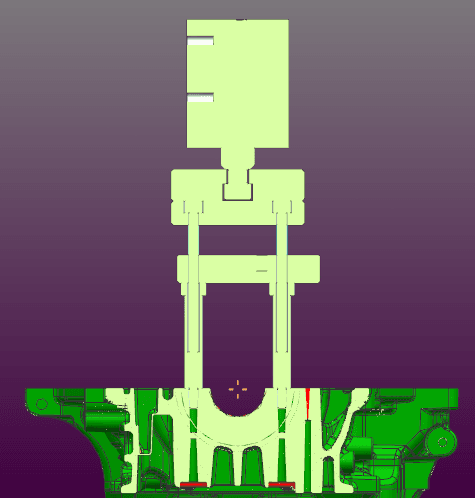

Step 3: Add Extrusion Pins

The thick wall still solidified late, cutting off pressure compensation after the gate froze. We added two extrusion pins near the defect area for secondary pressurization:

- How It Works: Pins act like mini injection heads, applying pressure (15mm depth, 2.5s delay) after initial filling to fill voids as the metal solidifies.

- Result: Scrap rate plummeted from 4% to 0.2%, with smaller, rarer pores in defective parts.

Alt: X-ray of engine crankcase post-optimization, showing a dense structure with no shrinkage porosity.

Key Takeaways

- Why It Forms: Shrinkage hits thick, hot areas where pressure can’t compensate for solidification shrinkage.

- Basic Fixes: Adjust pressure, cake thickness, and cooling to ease the issue.

- Ultimate Solution: Extrusion pins target thick zones with late-stage pressure, nearly eliminating defects.

After optimizing pin depth (15mm), delay (2.5s), and lifespan (8000 cycles), the scrap rate stabilized at 0.2%. Shenzhen Yuge applies such practical solutions to ensure high-quality die casting for critical parts.